How To Build the Ultimate DIY Workbench

POP Projects is a collection of new and classic projects from more than a century of Popular Mechanics. Master skills, get tool recommendations, and, most importantly, build something of your very own.

A DIY workbench can be utilitarian and thrown together or it can be beautifully handcrafted. Both can function about the same, but it's more likely the latter example will be a pleasure to use and to own.

When Popular Mechanics asked me to design and build a workbench as a project and as a centerpiece of its New York workshop and studio, I knew the bench had to reflect the brand and its no-nonsense heritage. I wanted it to have crisp lines and pleasing proportions. But most important, it had to be functional. It would be a bonus if, somehow, the bench reflected the magazine's association with house construction. Popular Mechanics has covered the topic for more than a century, and has published books on building your own house.

So I decided to build the bench out of construction lumber–clear Douglas fir, LVL joists (which are like large sheets of plywood) sawed into narrow strips then glued into a slab, and MDO, a form of plywood with a laminate surface.

The bench is ambitious, but it can be built by a home craftsman who owns a small table saw and a benchtop planer. Here's how to build one for yourself.

First, You'll Need Some Tools

Next, Let's Talk Materials

Now, About That Benchtop

The bench is not difficult to build, but it requires a methodical construction process. If you follow the procedure carefully, you get a massive top that's flat, square, and needs hardly any cleanup after it's glued together. The top has four rows of bench-dog holes bored into it. Specialized hardware called bench dogs fit into these holes, and when combined with other accessories and our Yost woodworking vise, the benchtop can hold a workpiece of just about any shape or reasonable size.

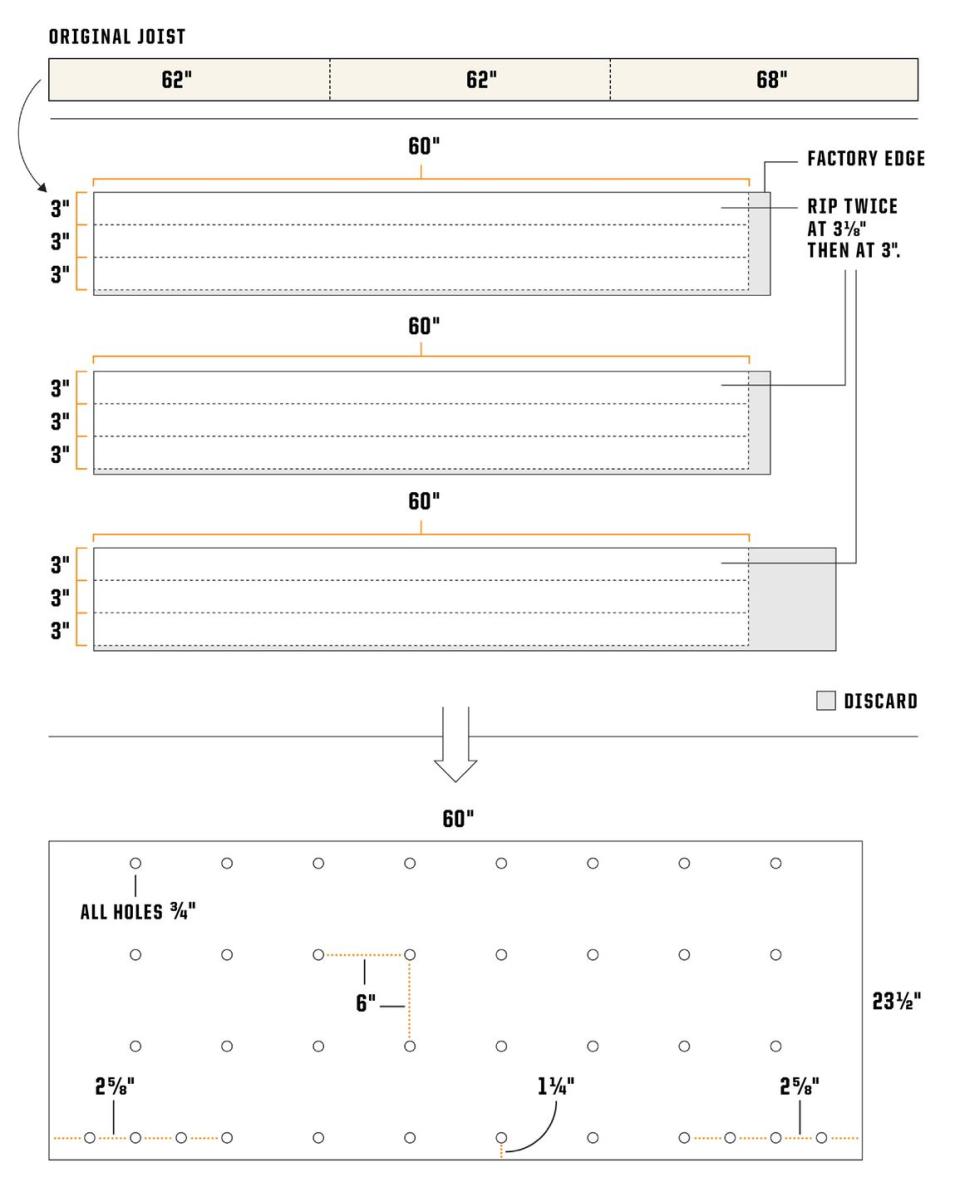

Making the top begins at the lumberyard. We purchased two LVL joists. These are like massive sheets of plywood. Each measures 13⁄4 inches x 91⁄2 inches wide by 16 feet long. To make them more manageable we had the lumberyard crosscut them into two 62-inch lengths. The remaining offcut was 68 inches long.

Next I installed a fifty-tooth combination rip–crosscut blade on my table saw. This is the perfect blade for neat ripping operations. The deep gullets at the base of its teeth keep the blade running cool, and this helps prevent burn marks on the lumber.

💡Lee Valley & Veritas makes accessories sized to fit into ¾-inch-diameter holes.

Let's Start Building

(1) Start Cutting: Set the saw fence to 3 1⁄8 inches and make the first ripping pass. Be sure to use a push stick as you near the end of the cut. Make one rip pass on each of the six pieces of LVL. Use a woodworking square and a straightedge to check the ripped edge for square and flatness.

(2) Rip Again: Now shut the saw off and reset the fence to 3 inches. Take each of the six pieces that you ripped, place the freshly sawn edge against the saw fence and feed the piece through the saw again. This produces six pieces of LVL with two sawn edges and no factory edge. Why bother? This ripping method eliminates the factory edge and its minor imperfections.

(3) Planing: Rip the remaining LVL pieces to 3 inches wide. Always place the freshly sawn edge against the table-saw fence.

When you're done, select the best fourteen 3-inch-wide pieces. Each should have two neatly sawn and perfect edges.

Next, carefully examine the face (the 3-inch width) of each piece and use a block plane to remove any small bumps where two pieces of veneer overlap. Making an extremely light cut, feed each piece through a benchtop planer to produce a consistently flat and straight surface free of the waxy -protective coating that's applied to the joist at the mill.

(4) Glue: After planing, crosscut the pieces on a miter saw using a stop block to produce a consistent length.

Now bring four LVL pieces to a reliably flat work surface and apply glue on the face of each piece using a foam paint roller. Clamp the pieces together using the rest of the benchtop pieces as a reference plane and a clamping block.

(5) Align: Use a rafter square to ensure that the pieces stay aligned.

(6) Clamp: Use cauls (sturdy pieces of lumber that you clamp down across the top of the assembly) to make sure that the assembly stays flat. Cover the cauls with wax paper to prevent glue from sticking to them.

When the glue has cured, repeat this procedure to glue the next three pieces of the top (don't glue the first four pieces to the next three pieces). Clamp this three-piece subassembly between the four-piece assembly on one side and the rest of the loose benchtop pieces on the other side.

Repeat this with the next three LVLs and the remaining four. You should be left with two three-piece assemblies and two four-piece assemblies. If you're tempted to skip this multistep process, don't. It's easier to glue up small assemblies than a large one.

(7) Bore Holes: Next, lay the glued-together subassemblies on a flat surface. Measure and mark the centerlines of the holes for the bench dogs based on the diagram on the opposite page. Separate the pieces and continue the reference line for the bench-dog holes down the face of each piece. Install a 3⁄4-inch brad-point bit in the drill press and mark a reference line on its fence to match the center of the bit. Now take each glued-together three-piece and four-piece assembly, align each mark for a bench-dog hole with the one on the fence, and bore the holes in its edge.

(8) Router: Complete the top by gluing and clamping the four sections together. After clamping, use a cabinet -scraper to remove any hardened globs of glue.

Now flip the top over and mark the outline of the mounting pads for the Yost vise. The benchtop is thicker than the vise is designed for so you need to cut a 5⁄8-inch-deep recess for it. Relative to those lines, clamp a straightedge across the benchtop to guide a plunge router to cut the recess.

Sand the benchtop with 100-, 120-, and 150-grit sandpaper, and wipe on a coating of Watco Danish Oil Finish and install the vise.

(9) Make the Base, Mount the Top: Begin by crosscutting 2 x 4 and 4 x 4 lumber for the base using a miter saw and stop block. Then feed these shortened sections through the planer to reduce their thickness. Each piece of 4 x 4 is reduced to 3 3⁄8 inches in both dimensions and the 2 x 4s are reduced to 1 3⁄8 x 3 3⁄8 inches.

Install a dado blade in the table saw and use some scraps from the 4 x 4 to test the setup, then cut the dadoes and notches in the bench legs.

Our bench was built with a back panel for aesthetic reasons only. It serves no structural purpose. You can omit this feature, but if you decide to use it, then cut a shallow 3⁄8-inch-deep groove in the legs using a router with a 3⁄4-inch-diameter bit and a fence.

(10) Clamp Legs: Next, dry-fit the legs and cross supports by clamping them together. Use a rafter square to check the assembly. With the parts still clamped together, bore the through holes for the carriage bolts.Sand the legs and cross supports with 100- and 120-grit sandpaper. Use a small router and a chamfer bit to ease the corners on the legs and cross supports.

(11) Sand Legs: Sand the legs and cross supports with 100- and 120-grit sandpaper. Use a small router and a chamfer bit to ease the corners on the legs and cross supports.

(12) Finish Legs: Wipe on a coating of Watco Danish Oil Finish to the legs and cross supports, then bolt the base together. Now mount the top. The benchtop is flush to the outside surface of the base on the back. Center the top on the base left to right, bore 1⁄4-inch pilot holes through the cross supports and into the top. Drive the 3⁄8-inch lag screws into the top.

Now that the bench is complete, build something great.

You Might Also Like