How the Obscure Science of Rubbing Built the Past and Will Shape the Future

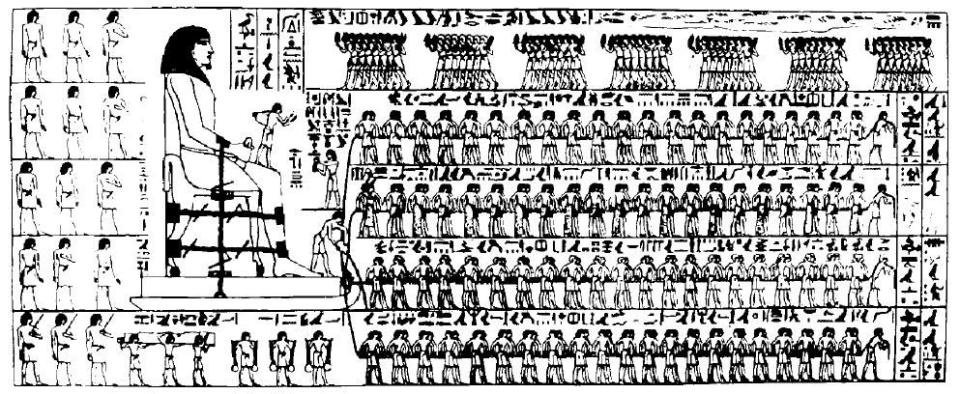

As early as the Stone Age, hominids realized if they patiently rotated a dry wooden stick back and forth in the hollow of a limb, they could successfully kindle a fire. Ancient Egyptians, meanwhile, discovered lubricants such as oil, lime, and water allowed for easier transport of building materials and increased the speed of their chariots. And in the Bible, Noah sealed his arc with bitumen to make the vessel more hydrodynamic.

These are all early examples of budding engineers practicing “tribology” (from the Greek word tribos, “to rub”), the field devoted to the study of interacting surfaces in relative motion, including friction, corrosion, and lubrication.

It may sound like another obscure “ology” at first. But from a grandfather clock to a molecular protein to a roller coaster, every system is made up of connected parts—rivets, gears, cartilage, bone, wheels—that create friction and can break down without proper lubrication. The velocity created between those parts as they rub together can lead to removal of material at the surface; that is, to wear and tear.

While tribologists—specialists who work in the field—have traditionally focused on fatigue, waste, or failure in mechanical elements like these, recent developments in the field have pushed this little known branch of science into the spotlight. In fact, tribology’s influence on global energy consumption, emissions, healthcare and sustainability has never been more immediate.

Tribology’s applications now extend beyond the realm of mechanics: Biotribology, for example, might investigate replacing the body’s natural ball-and-socket hip joint with a smooth metallic ball at the head of the femur. Geotribology considers the friction of tectonic plates and giant glaciers, while nanotribology examines phenomena at a microscopic scale—disk drive storage, diamond-reinforced materials, even molecular sieves. Most recently, green tribology works to address environmental problems such as how to lubricate the mechanisms of a wind turbine.

How can a field so pervasive in nature and everyday life remain virtually invisible in both private and public spheres? In part, because tribology itself is built on unseen forces all around us.

Tribology Through the Centuries

While the term wasn’t coined until the 1960s, tribology’s first scholar lived over 500 years ago. Leonardo da Vinci wasn’t just an artistic genius, but a keen observer and engineer who understood friction was a limiting factor in the efficiency of his revolutionary machines. The artist’s sketches—initially dismissed as doodles until x-ray technology proved otherwise—distinguished between rolling and sliding contacts and identified surface roughness as a factor in material movement.

Nearly two centuries later, French physicist Guillaume Amontons published his findings on friction, laws that govern sliding surfaces and inform research today. In his 1687 work Principia, Sir Isaac Newton laid down the foundations of fluid viscosity, which led to the development of oil lubrication. The observations and experiments carried out by Leonardo, Amontons, and Newton form the basis for many modern tribological devices, from car brakes to shoe soles.

It’s perhaps surprising that anyone would devote a lifetime to the study of friction. But tribology, “the most important subject no one has heard of,” is actually a significant part of daily life: Each blink of an eye is lubricated with tears, each step we take requires grip, saliva lubricates the food that we swallow.

Surfaces as varied as yoga mats and iPhone touch screens are carefully calibrated for our touch, designed to be neither too slick nor too scabrous. Coins become worn as a result of continued contact with human fingers; the metal fillings in our teeth grind down; our kitchen knives dull with use and the rubber treads of our car tires wear out. Wear is such a universal phenomenon that rarely do two solid bodies slide over each other or even touch each other without measurable material transfer or material loss. But we often don’t consider such problems until we encounter them.

“Tribology is an afterthought: a technology used to solve a problem whenever there’s a new mechanical system,” Chris DellaCorte, senior technologist at NASA’s Glenn Research Center, tells Popular Mechanics.

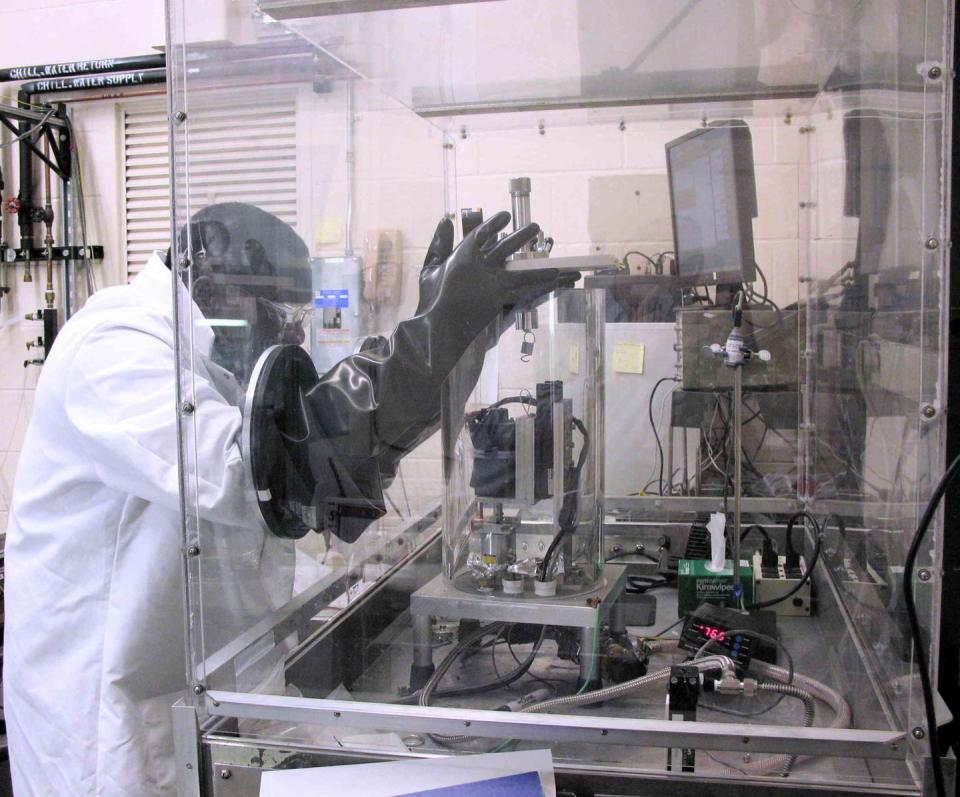

DellaCorte works on complex friction wear and lubrication problems across aeronautics and space missions: bearings that can turn at cold temperatures, and lubricants that can endure the high vacuum of space, withstand the dramatic vibrations of a rocket launch, and survive heat generated by aircraft turbines and engines.

“I like to tell people that my job is to make sure that things that are supposed to move keep moving, and things that aren’t supposed to move don’t,” DellaCorte explains. Advances in tribology, he adds, typically occur whenever society tries to do something new.

Consider that mankind’s earliest, and arguably most important inventions—fire, and the wheel—were actually attempts to work out tribological obstacles. The creation of fire required friction, while the wheel was a way to reduce friction. Millennia later, we continue to puzzle over these same basic principles.

In the 1990s, for example, when computer hard disk drives frequently crashed, tribologists developed fluorinated oils and diamond coatings to reduce friction. This meant disk drives could operate reliably, without wearing down during startup or shutdown. More recently, engineers discovered wind turbines withstood far greater gusts on actual mountaintops than inside testing facilities, which frequently led to their overload and breakdown. Better controls, special coatings and bearing alloys developed by tribologists allowed wind turbines to withstand high winds, which in turn conserved energy. In effect, innovations like these solve tribological problems and simultaneously reveal them.

Unimagined tribological challenges dot the horizon. Will electric cars generate spark discharges when we drive them across a wet road? Will satellite antennas unfurl properly in outer space? Will bionic limbs provide amputees with durable freedom of movement? Will the rovers we eventually send to Venus and Mars—chock full of moving mechanical assemblies—be able to withstand the extreme temperatures, corrosive acids and chemical dust storms of these interstellar environments?

“Tribology’s reach is far beyond comprehension,” says Evan Zabawski, Senior Technical Advisor at TestOil and a member of the Society of Tribologists and Lubrication Engineers (STLE), a group of scientists and academics established in 1944. Zabawski leads training programs in lubrication fundamentals, including function and performance properties, as well as industry best practices. Most of his course attendees have little familiarity with the subject, he says, and they often arrive armed with misunderstandings and so-called “tribology myths.”

“People assume that a can of WD40 can fix anything,” Zabawski tells Popular Mechanics. “They rely on faulty wisdom passed down through the ages, on those Jiffy-Lube stickers that warn them to change their engine after 3000 miles.” But different systems, in fact, require a wide variety of lubricants; elbow grease won’t always do.

Biological, marine, and aeronautical systems, for example, rely on a wide range of “third body” lubricants—that is, the slippery emollient sandwiched between two hard surfaces. Magnetic levitation between instruments keeps surfaces from rubbing together in zero gravity interstellar environments. Sewage systems may use air lubricants, and ship propellers use water and rubber bearings instead of metal to maximize energy efficiency and minimize corrosion.

To solve this problem of the third body in resistance, tribologists often look to the natural world. To help Olympic swimmers minimize drag in the water, for instance, tribologists turned to one of the most efficient swimmers on earth: the shark.

“By studying sharks, we developed a low-drag swimsuit that reduced friction by nearly a quarter,” says Zabawski. In fact, the shark skin-modeled suit helped athletes break 20 world records. Officials ultimately decided to ban its use, claiming an unfair advantage worse than steroids, yet the suit was a remarkable illustration of tribology’s potential to improve quality of life. “While it appears we went too far, this also showed we have much to gain,” says Zabawski.

Beyond the world of industrial engineering, tribology remains an almost sacral science: Most find the idea more theoretical than practical, especially given that the physics of surfaces is hard to describe or imagine. “There’s a lack of awareness because the technology is so diffused,” says DellaCorte.

Indeed, tribology is a highly interdisciplinary field, a branch of study made up of mechanical engineering, materials science, biology, mathematics, and others. To complicate matters, tribological problems—everything from adhesion (when objects become stuck on surfaces) to humidity’s effect on metallurgy—are often solved with practical, trial-by-error solutions, making them harder to identify.

As one of the earliest forms of resource conservation, tribology has, somewhat paradoxically, spurred incredible energy usage: Extending the service life of machines often delays the adoption of newer, more efficient designs. Yet, whether the aim is to prevent fatigue of our machines, protect equipment from corrosion, control temperature and contamination, transmit power, or provide a fluid seal, science friction, as it were, is increasingly relevant across industries.

Tribological applications allow human beings to interact with their solid planet, overcome the inconvenience of excessive wear, and mitigate the loss of time and precious resources. “We still have centuries of work ahead of us,” Zabawski says, “but tribology continues to impact our lives in new and inventive ways.”

You Might Also Like