Is AI the Answer to Sustainable, Humane Seafood?

A new tech company was inspired by a traditional Japanese method of slaughtering fish.

Food & Wine / Getty Images

The seafood industry has a problem. As demand for fish and shellfish soars and the ocean is pushed to the brink by overfishing, pollution, and climate change, nearly 90% of the world’s wild stocks are harvested up to or beyond their ecological limits. Yet 35 to 50% of this catch never makes it to our plates. The culprit? Destructive fishing methods and a broken, outdated supply chain.

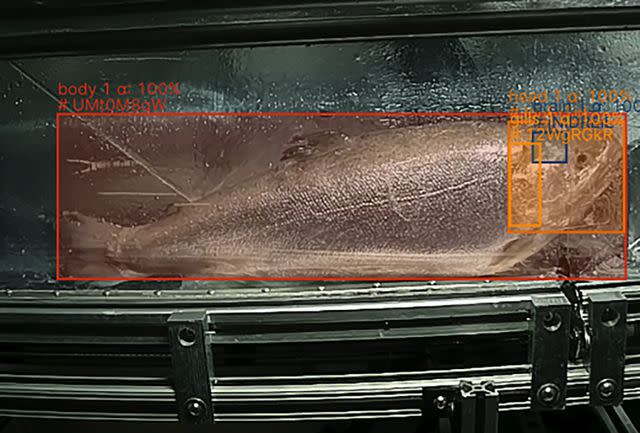

Shinkei Systems wants to solve these issues by automating a more humane and sustainable slaughter technique: ike-jime, a centuries-old, traditional Japanese method that involves carefully spiking each fish in the head to cause immediate brain death. Shinkei Systems has raised $7 million in seed funding and hopes to have 10 AI-guided machines in use by the end of the year.

Saif Khawaja, Shinkei’s founder, was inspired to act after reading philosopher Peter Singer’s essay “If Fish Could Scream” and remembering childhood fishing trips on the Red Sea. “We would put the fish in a cooler box, close the top, and hear the fish slamming on the side — it was super jarring,” says Khawaja. “It takes them a very, very long time to knock out.”

Slaughtering fish quickly isn’t just a moral decision, but a financial, logistical, and culinary one. If you’ve eaten high-quality sushi, the fish on your plate was almost certainly killed using ike-jime for the simple reason that it tastes better.

Ike-jime slows down decomposition significantly by destroying fish’s nervous system and preventing blood from reaching the muscles. After piercing the brain, ike-jime requires cutting and bleeding fish at the gills and tail, then severing the spinal cord with a sharp wire (Shinkei currently has this last part in prototypes).

“Every additional step you do compounds the shelf life, compounds the flavor, and compounds the texture,” says Khawaja. “When fish suffocate, they produce stress hormones like cortisol and adrenaline that make their muscles tense up. They’re flopping around, getting cuts and bruises. The muscles produce lactic acid, which makes the meat taste more acidic. Acidic meat is prime for bacteria growth, and blood provides nutrition for bacteria. It’s like the perfect petri dish.”

But performing ike-jime properly takes practice, time, and patience — which many large-scale fisheries can’t afford. Now, thanks to Shinkei’s computer vision, it’s possible to dispatch one fish for the process every 10 to 15 seconds.

"“A lot of people haven’t really experienced how good fish can be and you don’t really know until you go to one of these high-end restaurants. Once we scale robot production, we can reach the high-volume producers and democratize access.” — Saif Khawaja, founder of Shinkei Systems"

“It takes a lot of work to get fish to the level of a three-star Michelin restaurant,” says Khawaja. “That’s why [most] fish are so expensive. They’re very perishable. But if you handle it right, there’s a ton of upside. That’s where we come in.”

Fish killed using ike-jime can last for weeks stored in a vacuum sealed bag or airtight container. When implemented at a larger scale, this method has the potential to reduce waste, cost, and emissions by allowing fish to be shipped by freight rather than air, says Khawaja.

Shinkei is currently being used in the United States by the likes of Local Coho, a salmon farm in upstate New York that sells to restaurants including Nobu, and Yama Seafood, a distributor for Michelin-star chefs in New York City. Ultimately though, Khawaja aspires to build Shinkei into a company that benefits as many people (and fish) as possible.

“We’re already seeing the quality,” says Khawaja. “But how can we maximize that? A lot of people haven’t really experienced how good fish can be and you don't really know until you go to one of these high-end restaurants. Once we scale robot production, we can reach the high-volume producers and democratize access.”

For more Food & Wine news, make sure to sign up for our newsletter!

Read the original article on Food & Wine.