Early start to maple sugar season in New Brunswick

Things are getting a lot busier a lot sooner at Dumfries Maples.

It's barely March, but already the sap is running at the maple farm about 40 kilometres west of Fredericton — and has been since late February.

Simon Mitchell, who works at Dumfries Maples, said the weather pushed up the sap run from the past couple of years when they couldn't start production until mid-March.

He said the sweet spot for maple syrup production is cold nights below –5 C with daytime highs around 5 C.

"It's that freeze/thaw cycle that starts to get the sap moving in the tree that was frozen in place when winter arrived last fall," said Mitchell.

While the province has seen some warm temperatures the past week, and is forecast to see more next week, Mitchell said he hopes winter isn't completely done with the province yet.

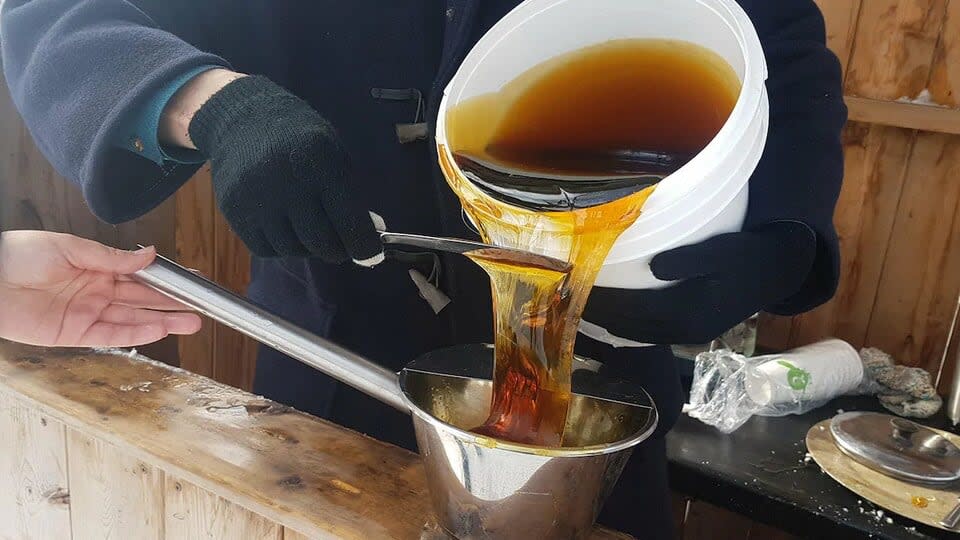

This file photo shows sap being collected from the tree. Most of Dumfries Maples' 5,500 taps are connected by a maze of long, rubber tubes that lead to two collection points, which are then sent to an evaporator where the sap is boiled down into maple syrup. (Francis Ferland/CBC)

"We want to, shall we say, stretch winter out a bit more and maybe not move into barbecuing season just yet," he said.

"Hopefully, we can extend that out until hopefully the third week of April."

When Dumfries Maples saw the extended forecast they started working on the sugar bush to get as long of a season as possible.

Most of the farm's 5,500 taps are connected by a maze of long, rubber tubes that lead to two collection points, which are then sent to an evaporator where the sap is boiled down into maple syrup.

While the system is a great deal more efficient than the old tap and bucket method of collecting sap, there's still a lot of maintenance involved.

"Deer and mice like to chew on the pipe because it's got a slight sweetness to it at times, and so you find holes and as we were going around tapping, we would be addressing those issues because you want the system to be functioning as efficiently as possible," said Mitchell.