Uniforms for Ukraine: Procurement challenges and risks unveiled — opinion

Ukraine's State Logistics Operator (DOT) has taken over the centralized procurement of clothing and equipment for the Armed Forces of Ukraine (AFU) starting Jan. 1, bringing significant changes to the supply of uniforms for the AFU, wrote Oleksandr Sokolovskyi, chair of the Committee for Defense Procurement of Light Industry of the Federation of Employers of Ukraine (FEU), for NV.

In early January, textile industry manufacturers and the Federation of Employers of Ukraine (FEU) held a joint press conference with the Ukrainian Defense Ministry and Economy Ministry after heated debates and social media exchanges. The parties appeared to reach an understanding and issued a joint declaration: "Ukrainian Uniforms for Ukrainian Defenders!"

Five months into the Defense Ministry's management of procurement, it's time to assess the initial results. On the positive side, manufacturers do not see any direct attempts by the ministry to engage in corrupt activities for personal gain. However, there are troubling risks that uniforms and other equipment may be delivered late and of substandard quality.

Why is this risk emerging? Instead of enhancing competition through a more flexible policy without lowering quality and deadline standards, the ministry attempts to "expand competition" merely by increasing the number of participants without a qualitative selection process. The ministry's well-intentioned aim to achieve cost savings may backfire.

How does the risk of supply failure arise?

Step 1: The winners of large contracts are often broad-profile intermediary companies that supply various goods. These companies typically lack their own production facilities, specialists, or experience in handling military contracts. Importantly, they do not have the long-standing reputations that genuine, experienced manufacturers fear losing. The "Hrynkevych case" at the end of last year exemplifies this, where contracts worth hundreds of millions for the Armed Forces of Ukraine (AFU) failed in terms of deadlines and quality. The Hrynkevychs were later accused of attempting to bribe the State Bureau of Investigations (SBI) with $500,000 to "resolve" these issues. By the end of 2024, there could be dozens of such "Hrynkevyches."

Read also: Armed forces of the world — opinion

Step 2: The intermediary winner delivers goods either late or of poor quality. Currently, the market is well aware of the "first swallow" — the company Golden Clover. These so-called "broad-profile specialists" have participated in and sometimes won tenders for supplying bulletproof vests, buckwheat, knitwear, socks, drinking water, ponchos, boots, hats, field mats, and more, despite not having their own production facilities for these items. They are intermediaries.

Earlier this year, Golden Clover won a tender due to very low prices to supply 80,000 summer field uniform pants for the AFU, worth 57 million hryvnias ($1.4 million), with a delivery date of March 31, 2024. By late May, they had delivered only 16,000 units, 20% of the plan, with a two-month delay. Summer has begun, but this is all they've managed to supply so far.

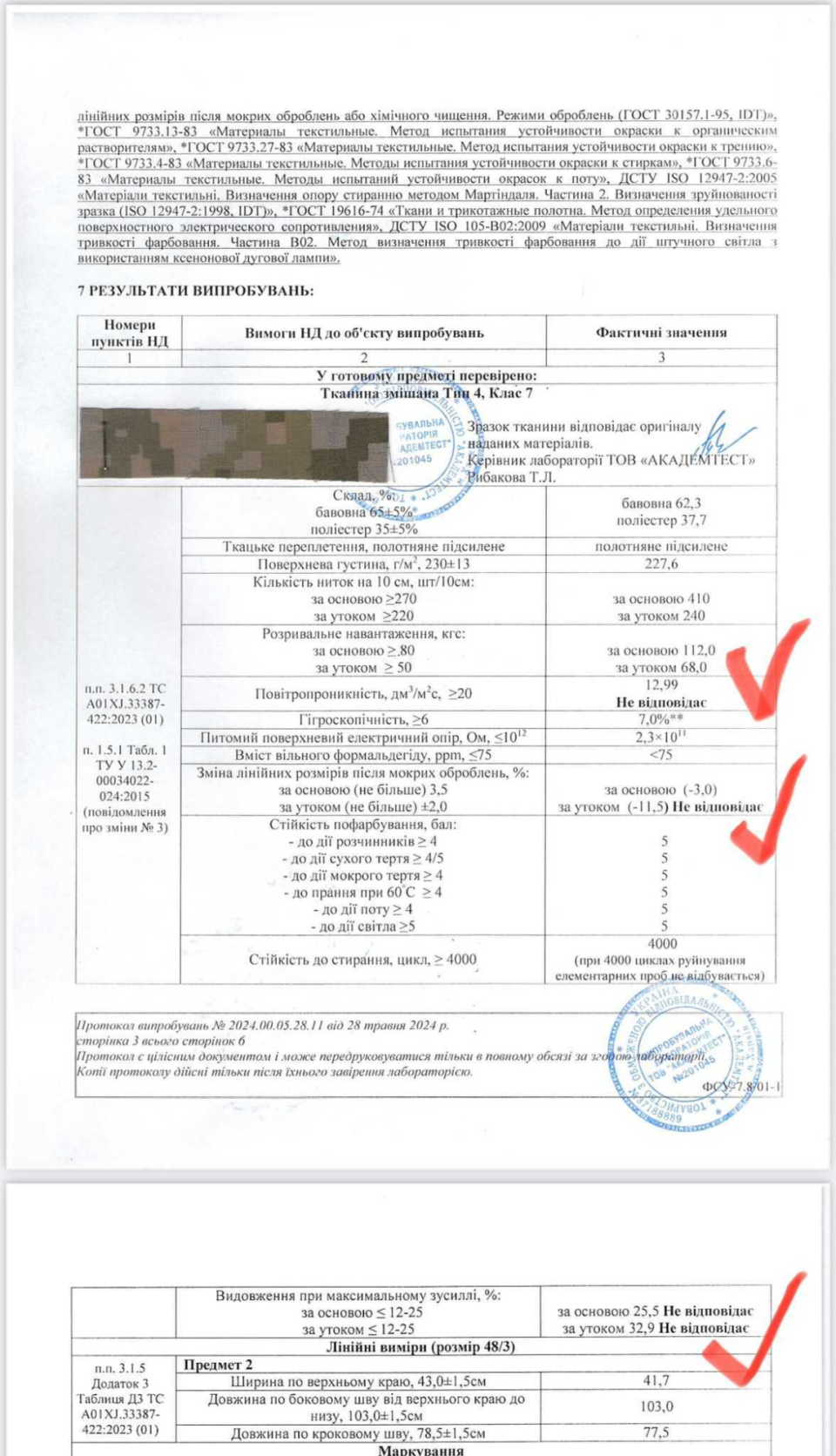

The main problem is not just the missed contract deadlines. An independent review found that the delivered pants do not meet the Defense Ministry's technical specifications. The fabric used is problematic; it does not breathe well (its air permeability is half the required standard), and it shrinks five times more than acceptable.

The poor air permeability means the uniform traps heat and moisture, potentially making soldiers unwell after a few hours of wear. The excessive shrinkage will cause the uniforms to shrink by one to two sizes after the first wash, turning a size 52 pair of pants into a size 48. Additionally, there are numerous other fabric-related issues with this batch, which the procuring authorities are hopefully addressing. However, compared to the fabric's problems, other issues like inaccurate sizing seem minor.

Step 3 (Expected): Heroic problem-solving

If these new intermediary suppliers fail by year's end, the Defense Ministry will need to find replacements. Experienced Ukrainian manufacturers cannot produce large quantities on short notice. Furthermore, ordering and producing raw materials takes up to three months. Manufacturers, wary of previous problematic collaborations with the Defense Ministry, do not keep significant stocks. Filling these gaps quickly may require importing finished goods from abroad, draining Ukraine's foreign currency reserves, costing Ukrainian jobs, and losing tax revenue for the budget.

Is such cost-cutting and supplier expansion at the expense of quality justified? Clearly not! Especially when the missing uniforms will still need to be contracted (possibly even outside of Ukraine's public electronic procurement system Prozorro through direct agreements due to deadline breaches) and end up costing more.

Read also: Ukrainian MP on tax hikes paying for mobilization — interview

Unfortunately, the Defense Ministry currently ignores Ukrainian manufacturers, particularly the large and capable ones. There is an unspoken belief that long-established companies in the textile industry are inferior to newcomer intermediaries with unknown production sites, possibly even in countries unfriendly to Ukraine. Moreover, the ministry employs a peculiar communication style: only meeting with individual suppliers, one-sided email communication, and no attempt to understand the industry's workings. Multiple proposals to form a working group to discuss procurement issues have been ignored.

Many large Ukrainian manufacturers, providing jobs to thousands and supporting the economy with taxes, do not feel needed by the state. Instead, preference is given to intermediaries and importers. It seems (and I hope I'm wrong) that the ministry's head Arsen Zhumadilov views capable companies with reputations, large production capacities, and experience in complex defense-related textile manufacturing as monopolists and unwelcome tender participants. This seems strange. Once again, I hope I'm wrong.

Both Ukrainian manufacturers and the State Logistics Operator share a common goal: timely delivery of quality uniforms to Ukrainian soldiers. Ukrainian manufacturers are confident they can win fair competition. Therefore, we hope the ministry and Mr. Zhumadilov return to the basic principles from which they began: fair contractor selection criteria, transparent and adequate technical conditions, reasonable delivery times, and proper verification of contractors' abilities.

Read also: Only four nations fund Czech ammo initiative for Ukraine

Recommendations

To address these issues, we propose several clear procurement approaches:

Suppliers must meet qualification criteria to fulfill a lot (sufficient number of employees, production equipment, laboratory reports confirming compliance with Defense Ministry technical requirements). If a supplier cannot produce even one quality sample before a tender, how can they be allowed to bid and then manufacture tens of thousands of units?

To ensure quality control of manufactured products, involve competitors who participated but did not win the tender. This principle has been used by national postal operator Ukrposhta with Ihor Smilyanskyi and Nadiya Bihun. No one will scrutinize products more thoroughly than a competitor specializing in the same type of production.

To increase competition, split large lots into smaller ones, gradually involve small Ukrainian manufacturers, and give them the chance to grow and prove their quality. Expanding the number of suppliers is necessary, but it must be done with an understanding that quality for the defense forces is a priority.

Read also: Ukraine may receive up to one million artillery shells from Czechia by year-end

Suppliers must meet qualification criteria to fulfill a lot (sufficient number of employees, production equipment, laboratory reports confirming compliance with Defense Ministry technical requirements). If a supplier cannot produce even one quality sample before a tender, how can they be allowed to bid and then manufacture tens of thousands of units?

To ensure quality control of manufactured products, involve competitors who participated but did not win the tender. This principle has been used by national postal operator Ukrposhta with Ihor Smilyanskyi and Nadiya Bihun. No one will scrutinize products more thoroughly than a competitor specializing in the same type of production.

To increase competition, split large lots into smaller ones, gradually involve small Ukrainian manufacturers, and give them the chance to grow and prove their quality. Expanding the number of suppliers is necessary, but it must be done with an understanding that quality for the defense forces is a priority.

Conclusion

Procurement for the AFU must ensure equal conditions for all participants. True competition, aligned with the defense forces' interests, involves non-discrimination of participants, reasonable supplier (manufacturer) requirements, uniform quality control procedures, standardized prepayment conditions, and adequate bidding and delivery times.

Including companies without production (of the relevant goods to be supplied) or importers from China, Turkey, or other countries is not competition. It is a crime against the Ukrainian army and economy. We hope the state and the Defense Ministry, as its representative, will understand this.

We’re bringing the voice of Ukraine to the world. Support us with a one-time donation, or become a Patron!

Read the original article on The New Voice of Ukraine